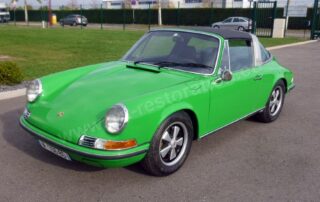

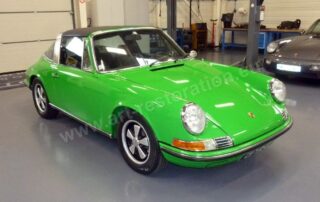

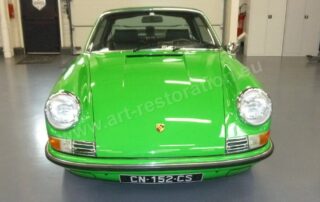

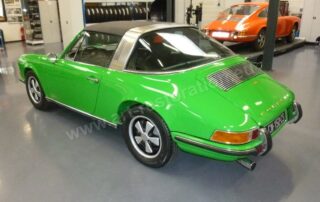

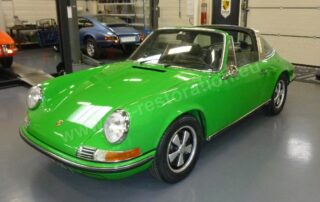

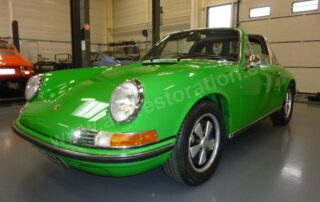

Discover here the restoration of a 2.2 S Targa from 1971. The engine, the transmission, the running gear and the interior have been refurbished. The underbody has also been treated. A real rejuvenation cure!

The paint on this car had just been redone when we started to dismantle it.

The engine, the gearbox, the running gear and the braking system are completely removed.

Then everything that needs to be sanded is dismantled. The injection pump is going to be refurbished at Bosch.

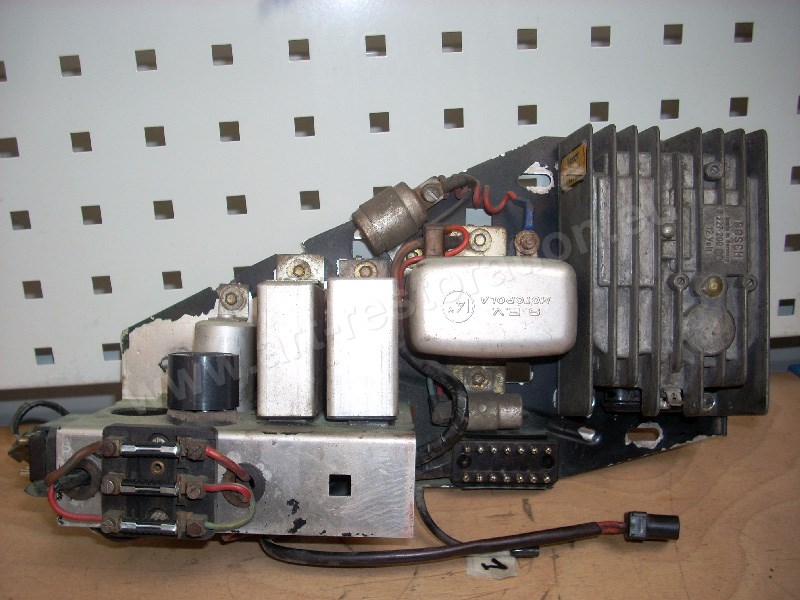

The transmission and the ignition plate will soon go to pot! The oil tank, thermostat, radiator and all pipes are removed.

The engine compartment and the front compartment are stripped to be cryogenically cleaned and repainted.

Complete dismantling of the engine and metrology of all its parts. The crankshaft is sent for grinding, one crankpin and one journal are 1/100 below the tolerance.

There is only wear and tear related to the engine’s mileage, but many parts are now “out of date”. As always, there are threads to be repaired.

All lubrication circuits are made 100% accessible for cleaning. All the joint plans of the housings are prepared. The crankshaft is ground and ready for a new life

The cylinder heads are de-grooved, the gasket planes are reworked, the valve guides are changed. The oil pump, intermediate shaft and crankshaft gear are new.

The connecting rods are balanced, the bushings changed. The cylinders and pistons from Mahle are new. The 12 valves are new. The cylinder heads are dressed.

Reassembly of the engine.

Once the timing is adjusted, the engine can be dressed. The injection pump is refurbished, the fan is painted.

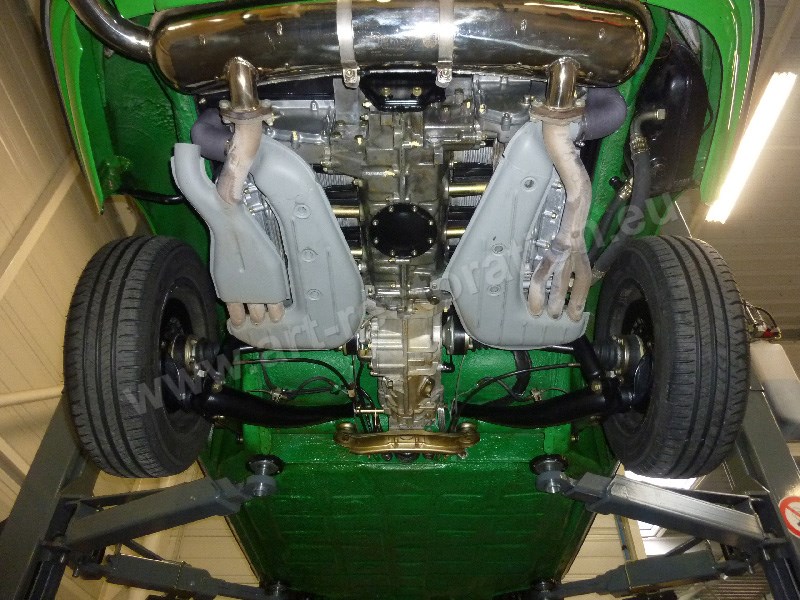

The underside of the box is completely cryogenically cleaned. Repairs are made, then a new anti-gravelling agent is applied.

A paint is applied as well as a protective wax under the whole surface of the car.

All metal parts of the engine and running gear are sandblasted.

Then chromated and epoxied.

All wearing parts are refurbished. We start by reassembling the gimbals.

The running gear is pre-assembled.

Then we reassemble the running gear on the car.

The original oil cooler is very fragile, it required a very delicate repair (the two connection threads remained on the pipes during disassembly …). The external hydraulic system is reassembled, the oil tank has also been repaired.

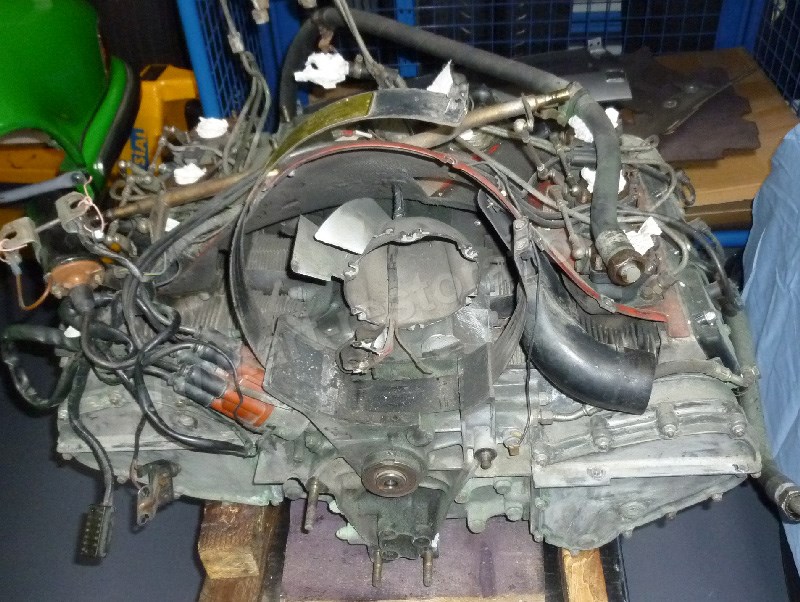

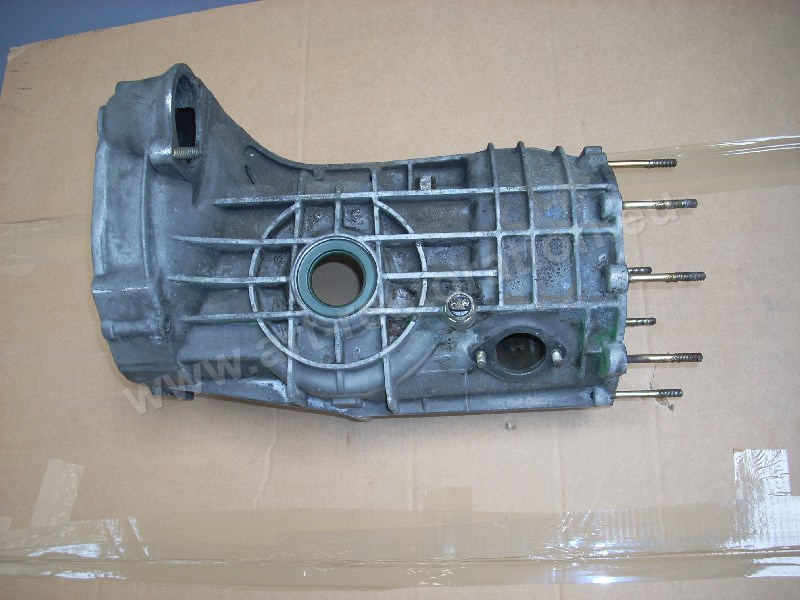

The gearbox is completely dismantled. A visual and metrological control is carried out.

Wear parts are changed, the casings are bead blasted, the seal faces are reworked, the studs are chromated.

Synchros and bearings are refurbished.

The reassembled engine and gearbox are started on a static bench before being returned to their place in the car.

I drive the first 1000 km, this distance allows me to make the necessary adjustments and to validate the reliability of the system. Before delivery to the customer, a supplement of wax is made, it is the yellow product that we see on the engine and on the body.

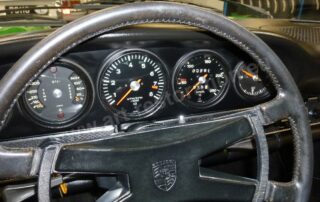

The interior was also removed to refurbish the door panels, door bins, carpets, dashboard, instrument panel and the Targa roof.

The meters have been revised, the bottom of the dashboard painted black. The door and roof seals have been changed and adjustments made.

The interior is great, one part new, one part old….

the tank has been painted, the front trunk carpets are new. The rims have been restored as original at Art-Wheels (in Strasbourg …).

The Conda green is even more beautiful on the road than in photos….

Mileage : Km km – Year : 1971 – Price : Sold