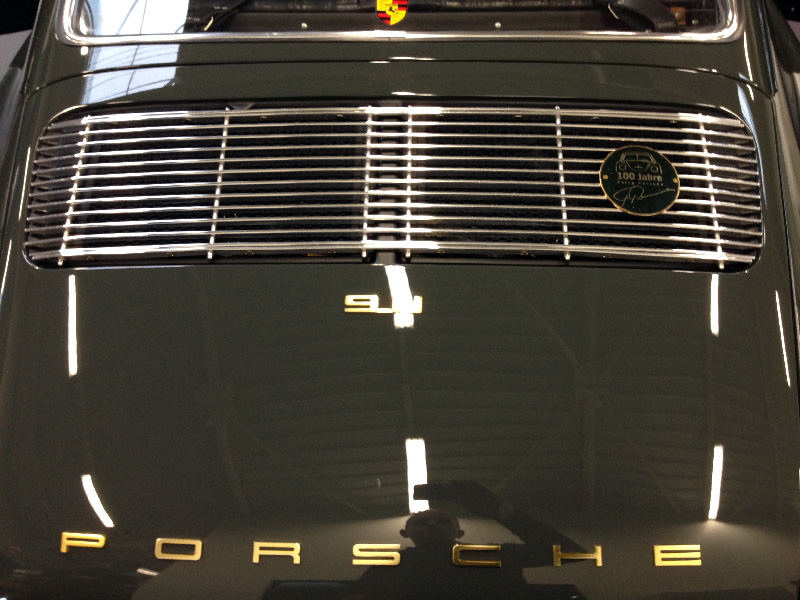

Discover here the restoration of a 1966 911 in much worse condition than we thought. A very long way to deliver a new car with some interior elements in their juice. In its original color Slate Grey 6601.

When she arrived, she looked tired but not in too serious a state. You could see some rust blisters in the usual places, not perfect alignments, and a lot of black Blaxon on the unpainted parts. The screwdriver still fits in quite a few places without much effort. His owner wished to redo the paint and restoration of his hull worthy of the name, we decided to make a chemical stripping and a cataphoresis to have a clean situation.

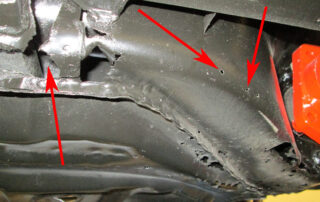

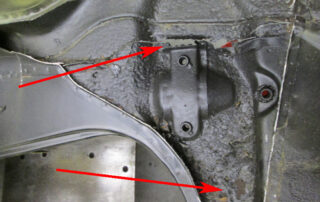

The return of cataphoresis was like a cold shower, we notice endless lace, no big shocks but old repairs too rough, the pictures speak for themselves.

The worst part was the floor which was changed by cutting all the docking edges and put back in place with angle iron. It was estimated that it would take approximately 350 hours to recreate just the docking edges of the floor…. Faced with the situation of this hull, the most economical solution is to start again with a less rotten and less “repaired” hull, if we can find one.

The weak point of the classic 911s being their addiction to rust, we end up finding a less severely rotted 1967 hull to use as a base for rebuilding. We will take back all the little details to keep 100% the authenticity of our model 66. such as the dashboard, steering column, Webasto fasteners, etc.

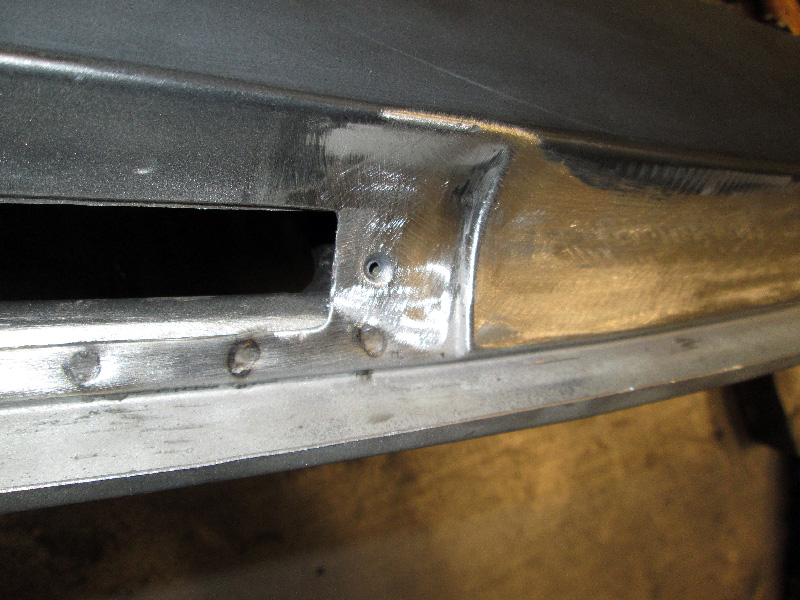

The upper parts of the wheel arches where the front fenders are fixed are often rusty, here we replaced them by the original ones in good condition. The entire floor will be replaced, but here the docking edges are clean!

The front spars will be rebuilt on both sides, here is an example of a more available outer spar.

The two inner parts of the stringers are available but not for year 66, so we have to modify the shape of the stringers before fitting and welding them.

The lower corners of the wheel wells towards the rocker panels are often drilled, here we make two pieces to replace the rusted areas.

The rear suspension anchor points are also often rusted, usually only a very small rusted area is visible on the outside, but the three reinforcement plates on the inside are almost always very rusty. Here we replace them up to the sound sheet, which will allow to recreate the floor docking in the rear part. This area of the hull takes a lot of stress, so it is important that it is in good condition for the rigidity of the hull. The same goes for the rocker panels on both sides that we are refurbishing, they contribute greatly to the rigidity of the hull.

The new floor is welded as original. The groove that receives the hood seal in front of the windshield bay is pierced by rust. We cut out the damaged area and manufacture a replacement part.

The lower parts of the windshield pillars are rusted, we cut them out and make shaped parts to replace them. We replace the top of the dashboard and weld it as original. The new door legs are adjusted and welded on both sides.

New rear fenders and door sills are adjusted and welded. The doors are repaired and adjusted. The new front fenders are adjusted and installed.

Hoods and bumpers are repaired and adjusted. Then the finishing touches of all the elements are made with tin only. The hull and its elements are carefully sanded and degreased before being primed with epoxy.

The painted parts are covered with a polyester primer which will be sanded to remove the last defects of flatness. Then a tinted primer finish will be applied and sanded to remove micro-scratches.

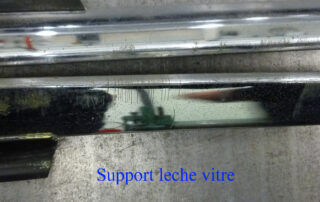

The black anti-gravel is carefully applied in the original areas, without overthickness, the welding points must remain perfectly visible.

The solvent-based direct gloss paint is applied in two coats on the hull and on the elements.

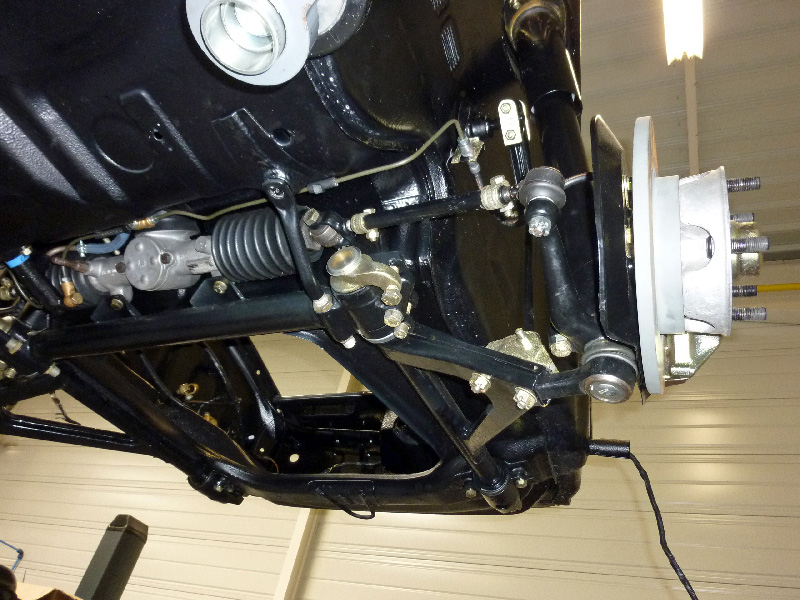

All parts of the running gear have been sandblasted, chromated and then a baked epoxy paint is applied.

The running gear is reassembled with new bearings, new ball joints and silent blocks, new shocks, new discs and pads, new master cylinder and piping…

The chrome parts were not very nice anymore, we disassembled everything to have the chrome plating done. Then comes the game of patience to assemble all the guides and handles as original with new rivets and joints.

The window lift and door opening mechanisms have been revised. So is the fresh air ventilation system. The pedal board has been refurbished.

The gearshift and handbrake system are also refurbished.

The wiring harness has been overhauled, reconditioned and positioned as original. The gas tank is new, the hoses and the fuel pump are new too.

The tarred soundproofing is glued as original. The original padded soundproofing is cut on site and glued as original. The carpets are new. The imitation side panels and rear deck are new.

The simili of the knee protectors is new, as is the stainless steel front. The imitation of the dashboard is vintage, we managed to take it off without breaking it to change the lower foams and glue it back. The result is great!

We repaired the hot air vents on the rear window and painted them in their original color. The roof sky is new. The oil cover has been repaired and painted with epoxy.

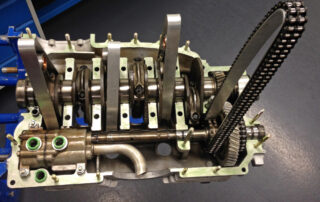

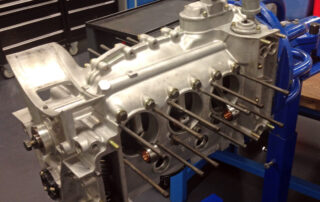

The engine was completely dismantled, cleaned and after a good metrology session we were able to proceed to its restoration. We changed all the bearings, all the seals, the oil pump, the intermediate shaft, the timing chains, the connecting rod rings. The cylinders have been re-bored and Mahlé pistons have been installed in the repair area. The valves and guides are new.

The flywheel and clutch are new. The Weber carburetors have been completely disassembled, de-sealed, ultrasonically cleaned and reassembled. The screws and the horns have been chromated. The exhaust line is new. The gearbox is also rebuilt, synchros, bearings and seals are new.

The first burnings took place in the presence of the owner, who honored us with his first visit on this occasion. Then comes the first refueling and the long period of driving to detect any anomalies.

980 kilometers later, it is finally ready to be delivered. The final finishing touches can now be made.

The front and rear seat similes are retained. The internal foams are changed. The door panels are new. The armrests and panel tops are period.

Two three-point seat belts are installed. A vintage tool kit and a Bilstein jack are also provided.

French 911, sold by Sonauto in July 1966. It then finds its yellow headlights and its Sonauto plate on the engine hood.

Mileage : km – Year : 07/1966 – Price :