Discover here the restoration of a 911, the sickest one we have ever had to treat. Its bodywork was badly eaten by rust and previous repairs. The interior was unsalvageable and the undercarriage badly rusted. Its transmission and engine were in normal working order inside… not like outside.

This car arrived at the workshop after a long period of immobilization. It had been modified into a G model and traces of the accident remain visible. Without hesitation, we started with a complete disassembly.

The hull is completely stripped to leave for chemical pickling and rust removal.

The black paint is an anti-rust treatment called cataphoresis, it protects what remains of the bare metal sheets against rust.

Discovery of rust damage and previous repairs. It is at this level that we become aware of the state of the bodywork and that we can take stock of the main parts to be changed.

The list of parts to be changed is long: complete floor, four wheel arches, four fenders, two door panels, front hood, front and rear side rails, front face, rocker panel…

The available sheet metal parts are procured before cutting begins.

The hull is placed on the marble, the removal of the damaged elements can begin.

We always start with the floor and the rear cross tube. The cross tube is not available as a replacement part, so we will resurrect another tube, this one being too rusty.

Then we go on with the reconstruction of the rear wheel arms fixing points.

This part of the hull is always rusty, the repair kits allow you not to start from scratch to repair.

It is then the turn of the lower part of the rear wall which is perforated, it will be repaired from a flat sheet and a little know-how. We will also rebuild the two Targa specific reinforcements and weld them together with the floor.

We attack then the two bottom of the front wheel arches which almost disappeared. We will use repair parts.

At this stage we have repaired all the docking areas to be able to weld the new floor that is placed on the marble. It will become our new reference to continue the repairs.

The front cell shows strong traces of accident and a lot of perforating corrosion, we are going to remove all the front cell and keep only the shock absorber caps and the upper trunk plate.

The remaining elements are repaired, the docking edges are prepared to have a good surface for stowing and welding the new elements.

The front panel, front side rails and fuel tank support plate are adjusted and welded into position.

It’s now the turn of the rear cell to be treated, we will change the two rear wheel arches.

The inner parts of the rear spars are repaired and the docking edges are refurbished. The rear crossbar is changed, also on marble.

The rocker panels and rear side rails are pre-assembled and fitted as a unit.

The Targa specific reinforcements at the rear are replaced. Rusty parts of the hoop are replaced by hand-formed parts.

The cross member above the engine hood is adjusted, prepared and welded in position as original.

All the elements (doors, fenders, hoods and bumpers) are mounted with the joints, locks, jacks to perfect the adjustment of each of them.

All stops and finishes are made with pewter, as original.

Then the elements are removed and the sanding of each surface is done to receive the epoxy primer.

Application of the epoxy primer which will serve as a protection against rust and as a grip for the following coats.

Application of polyester primer, sanding and application of finishing primer.

Application of the anti-gravelling tinted in the mass.

Painting of each element separately.

Hull and painted elements.

Blacking out certain areas.

At the same time, we are working on the restoration of the engine.

Complete disassembly, cleaning and metrology. Sandblasting of engine sheet metal.

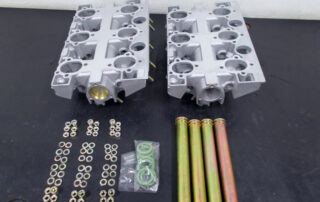

Change of valve guides, repair of threads and rework of cylinder head surfaces.

Change of connecting rod bushings, bearings, oil pump, intermediate shaft…. and start of the reassembly.

Repair of the camshaft supports. Chromatation of the screws. Reassembly of the valves.

Chromatation of engine sheet metal. Reassembly of new valves, new cylinders and pistons.

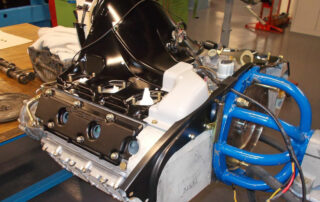

Low engine assembly and timing.

Engine cladding.

Mounting of motor peripherals.

Restoration of carburetors and intake pipes.

Engine ready to be mounted in the car. We’ll move on to the restoration of the gearbox.

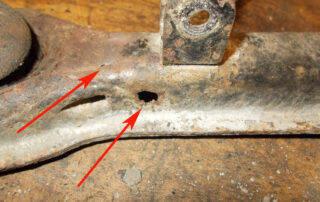

Discovery of a crack on the nose cone, we will have to replace it, fortunately a new model is still available.

Bearings, retaining plates and synchros are very sick. We’re going to have to change all that to get this transmission back on track.

The running gear is not spared from rust. The triangles are perforated, no need to sand them, we will simply change them. All other parts are sandblasted.

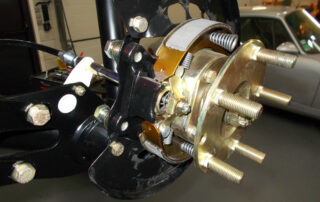

All metal parts are chromated and then an epoxy paint is applied and baked.

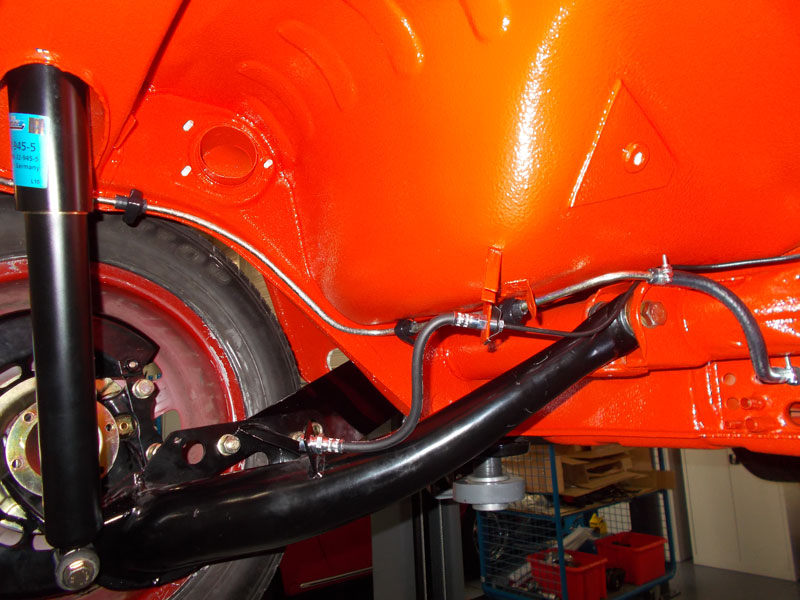

Reassembly of the running gear with new silentblocks, new bearings, new shock absorbers… all new.

The pedalboard undergoes the same treatment.

Assembly of the running gear on the hull.

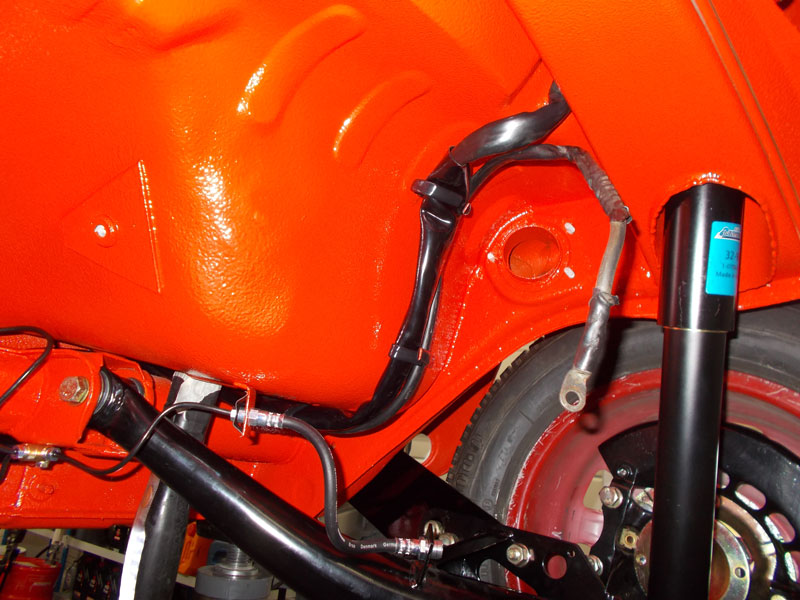

Assembly of the braking system.

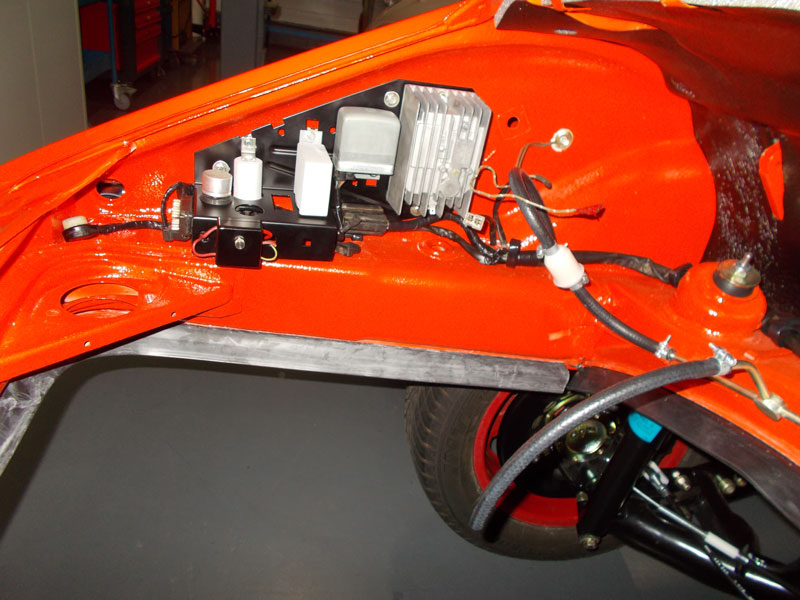

Repair of the electrical harness and then assembly.

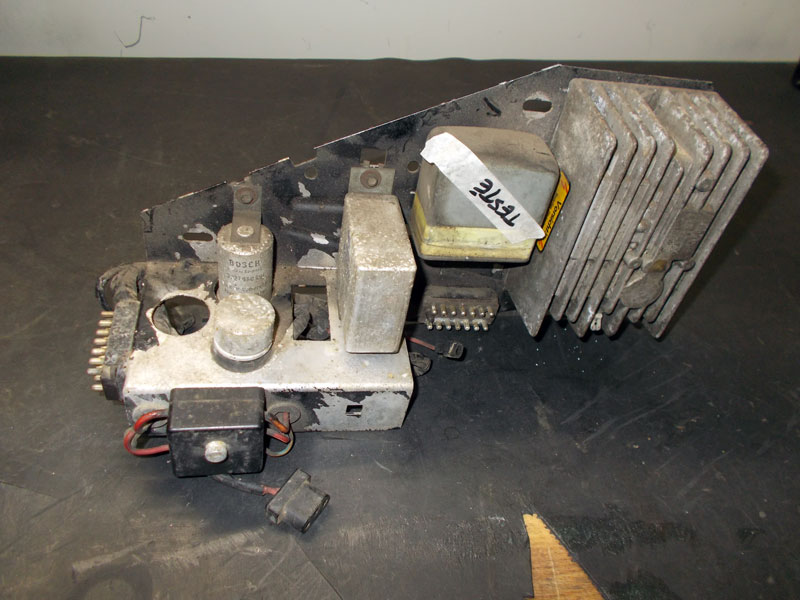

Restoration of the ignition plate.

Installation of the various insulations, as original.

Assembly of the fuel system. Restoration of the folding soft top.

We change all the canvas and the imitations of the soft roof. Its aluminum structure is also refurbished.

Installation of the meters and the equipment of the dashboard which have been previously repaired.

The carpets are glued. The heating and fresh air systems are refurbished and installed in the car. The windshield wiper system is overhauled and reassembled in place.

The motor-box unit is installed in the car. The windows are also mounted.

The stainless steel roll bar is refurbished and installed in the car. Lights, rods, lettering and grills are installed.

The 911 is ready for its first runs.

The interior is finished.

After about 1000 km of tests, all the adjustments are made so that there is no air noise, water infiltration and vibrations. All checks are done.

Before delivery, a protective wax is applied under the entire shell.

Mileage : 962 km – Year : 1971 – Price : Customer car