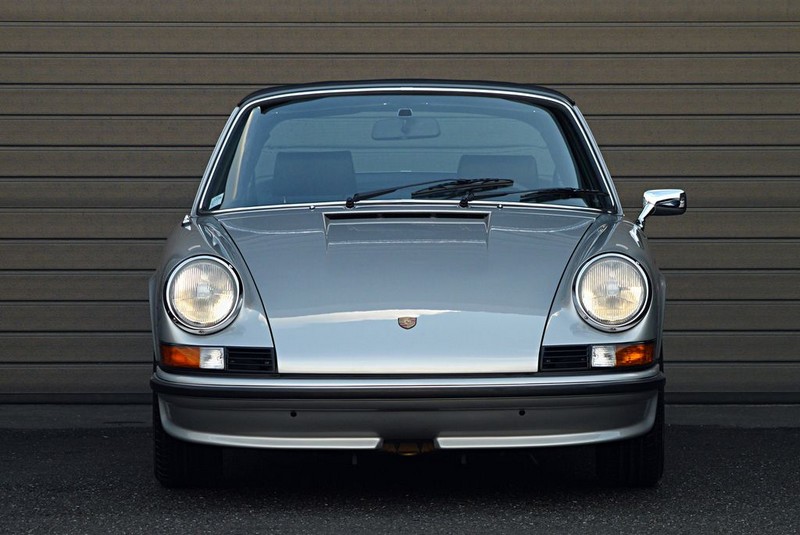

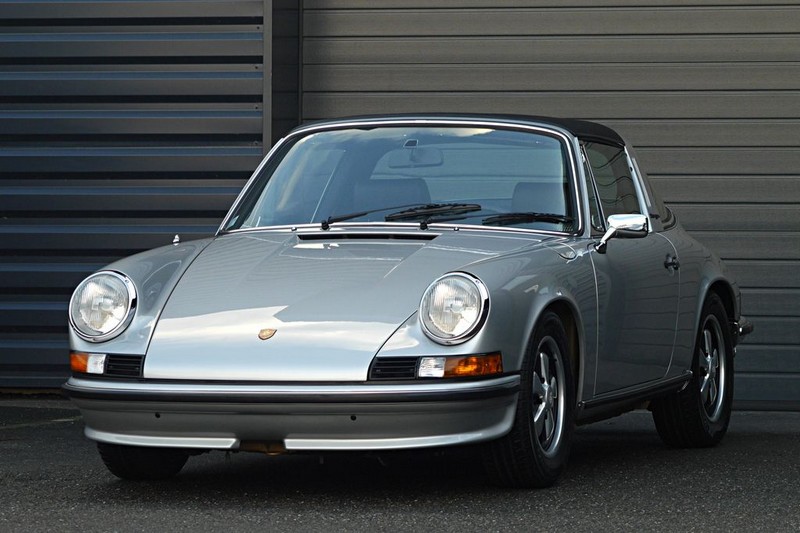

Porsche 911 2.4S Targa. The car seemed to be in good enough condition when it arrived, but the surprises are going to follow one after the other during the dismantling.

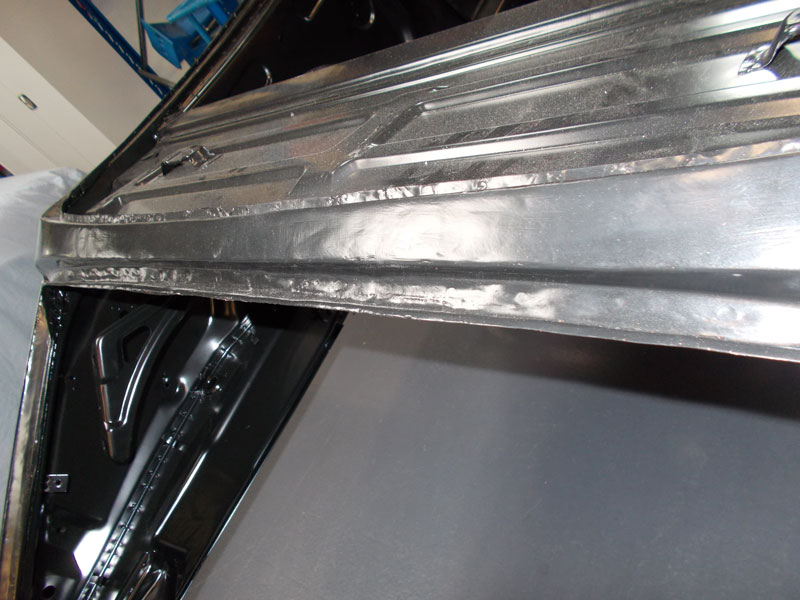

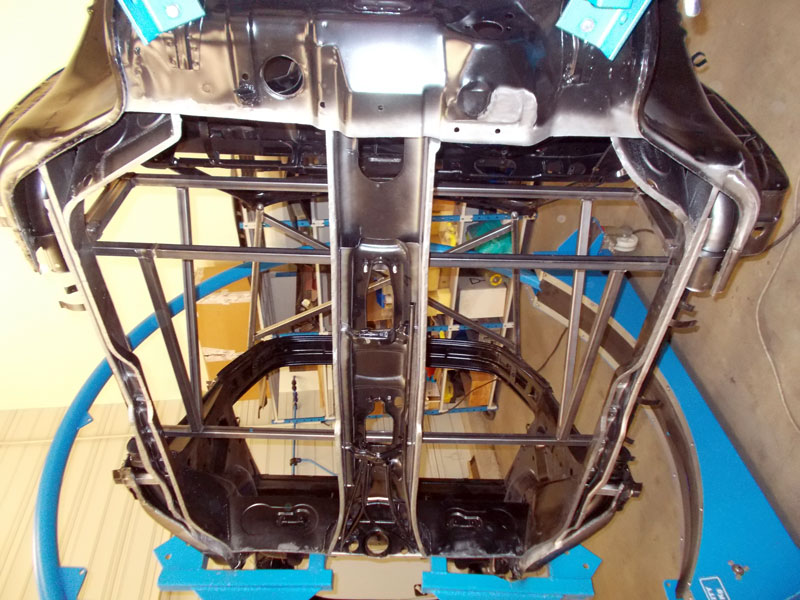

At this stage of disassembly, the hull seems heavily chewed, traces of repair are visible, but we do not know yet what it hides.

Start for chemical pickling, chemical derusting and cataphoresis.

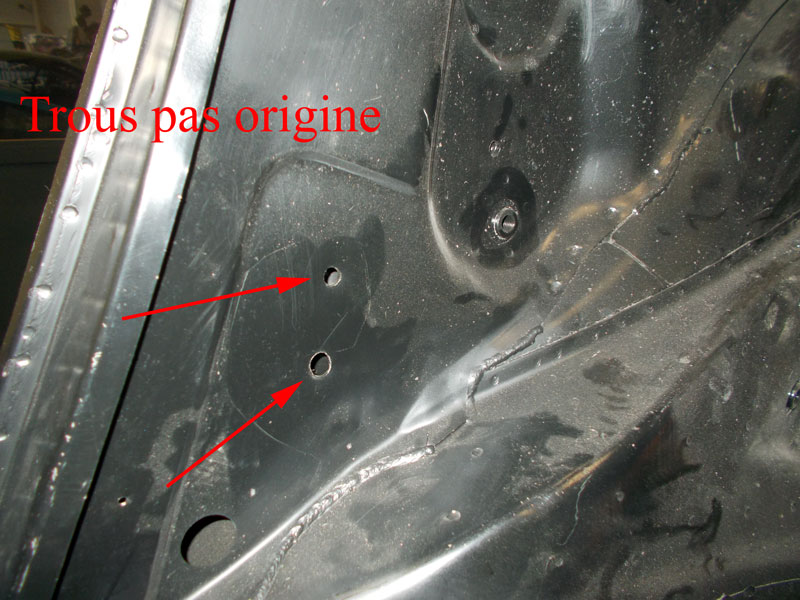

Discovery of anomalies upon return from cataphoresis.

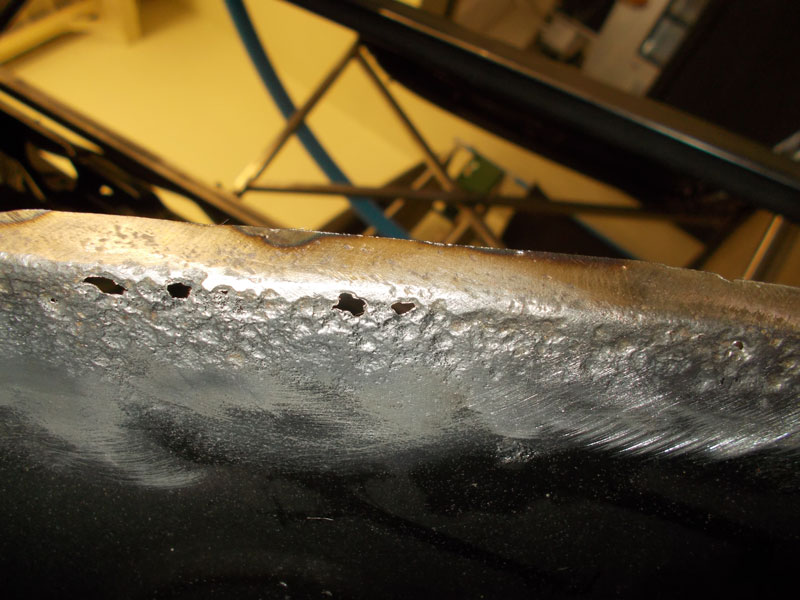

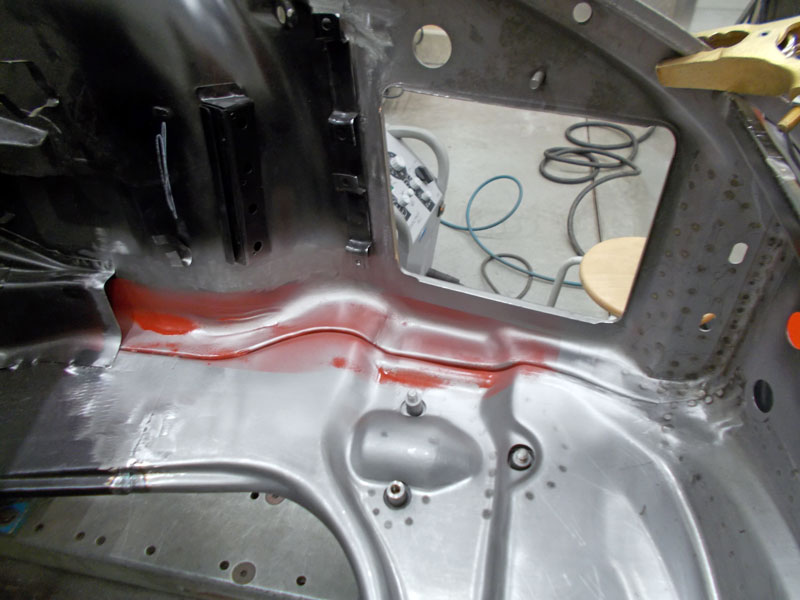

Underneath the putty, rough repairs appear.

Presence of patches and rusty areas. The window for the car radio has been enlarged roughly.

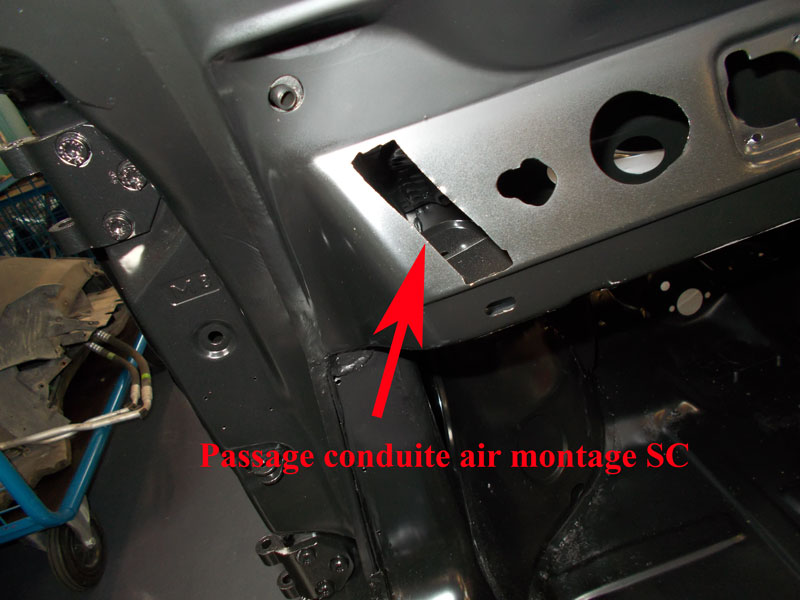

SC style holes have been cut in the dashboard. The floor is badly damaged.

The rocker panels are gnawed, the fenders are hammered. The rear wing cheek has been roughly modified. The rear crossbar is also deformed.

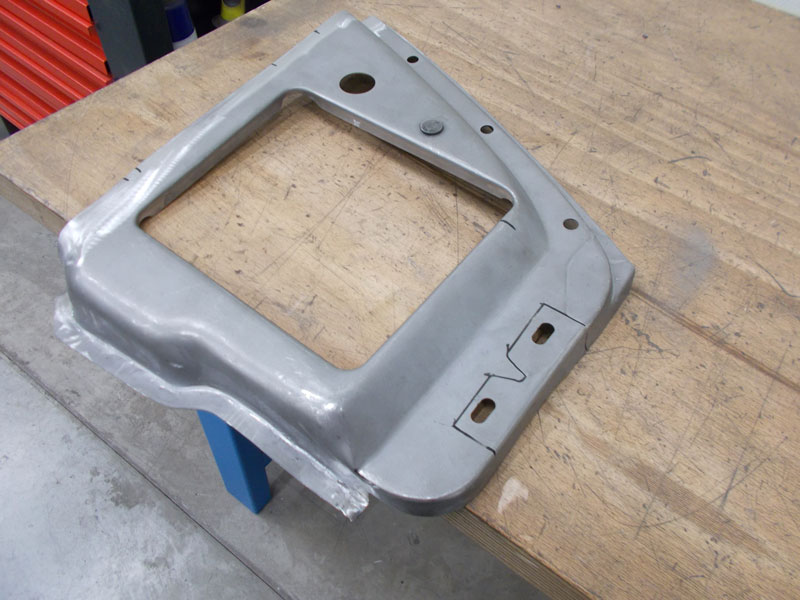

The main new parts to be changed are shown on the ground…. Beginning of the sheet metal work.

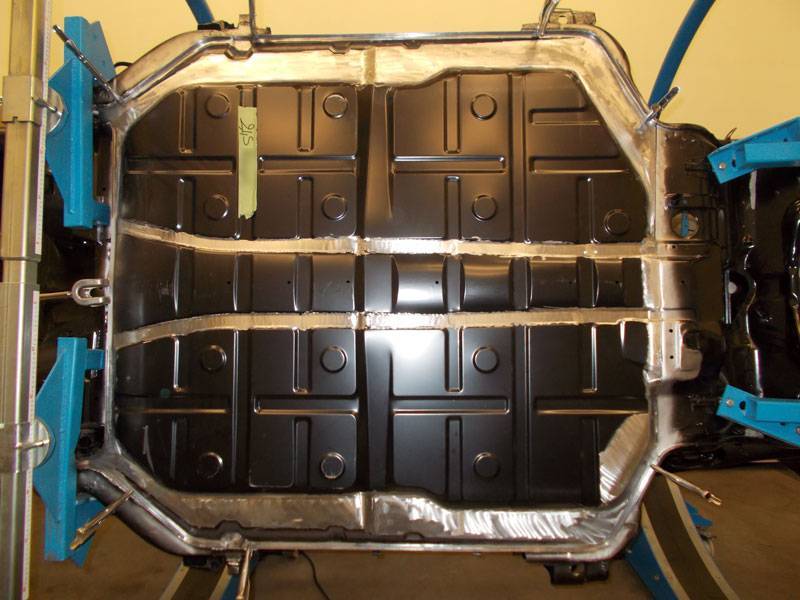

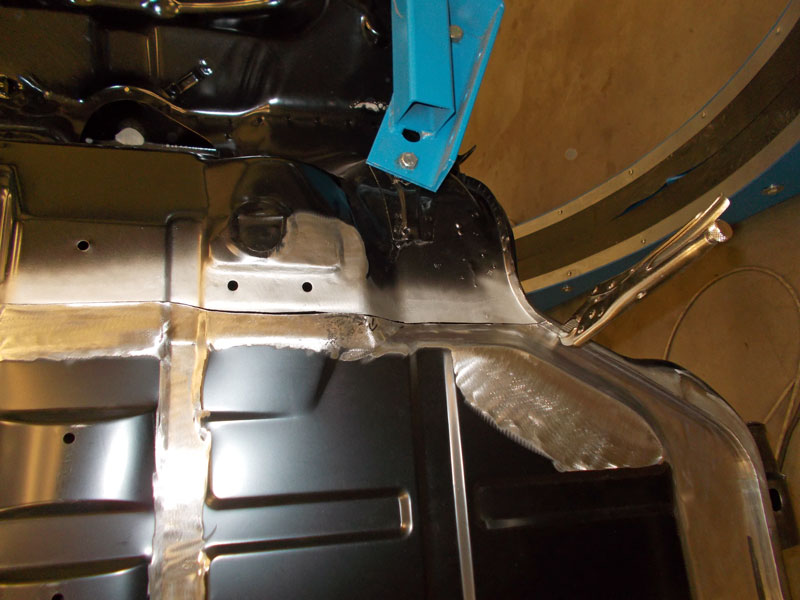

The first step is to restore the floor.

Repair of the intermediate wall and floor supports.

The docking edges of the floor are rebuilt to new before presenting the floor in position.

Adjustment and welding of the floor.

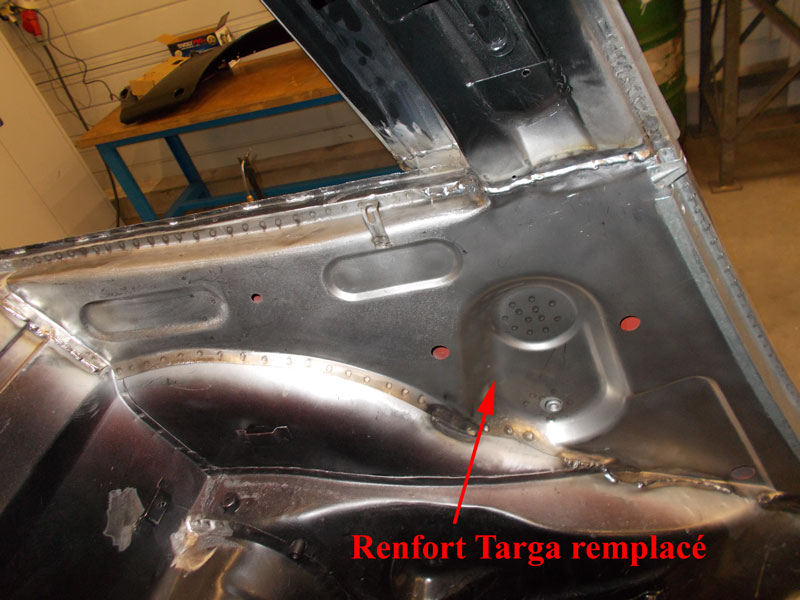

Welding of Targa reinforcements.

Repair of dashboard anomalies.

Now it’s the turn of the front cell repair.

We are going to change the front face, the front floor, the front spars and the nose of the front wheel arches.

Adjustment and welding of the front floor.

Adjustment and welding of the front face and the half-beams.

Now we move to the repair of the right rear wheel arch.

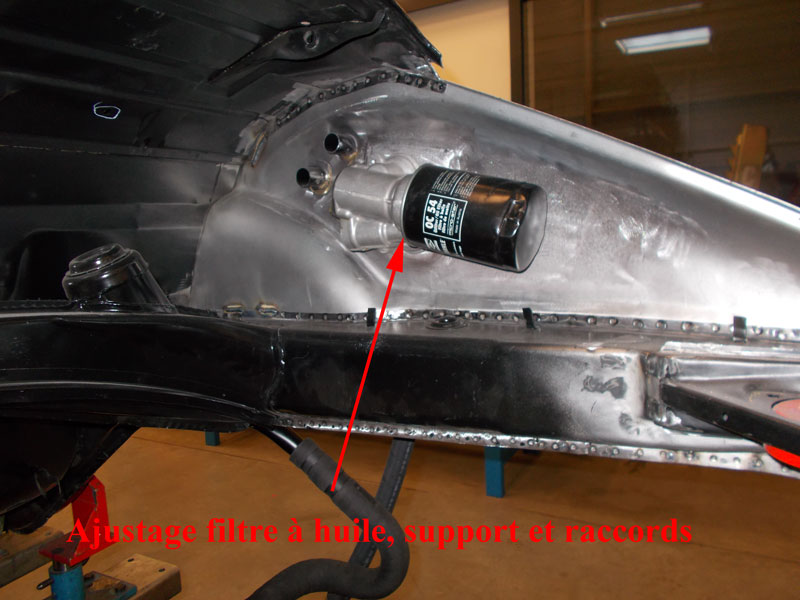

Manufacture of the oil filter support area.

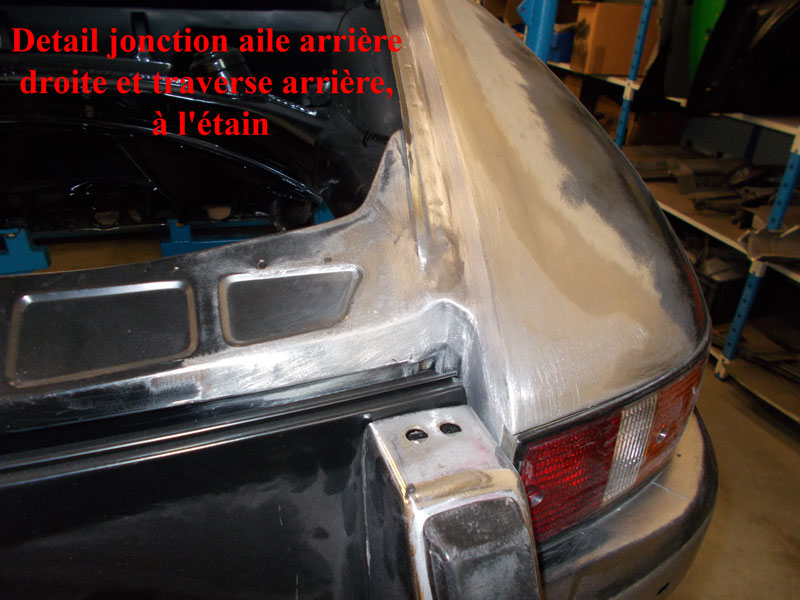

Change of the rear crossbar.

Adjustment and welding of the rear wheel arch.

Repair of the bases of the arch.

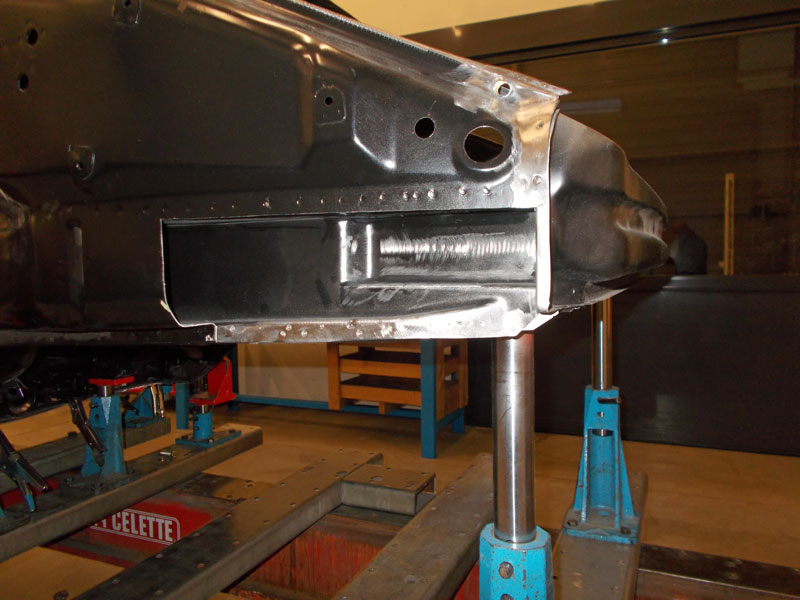

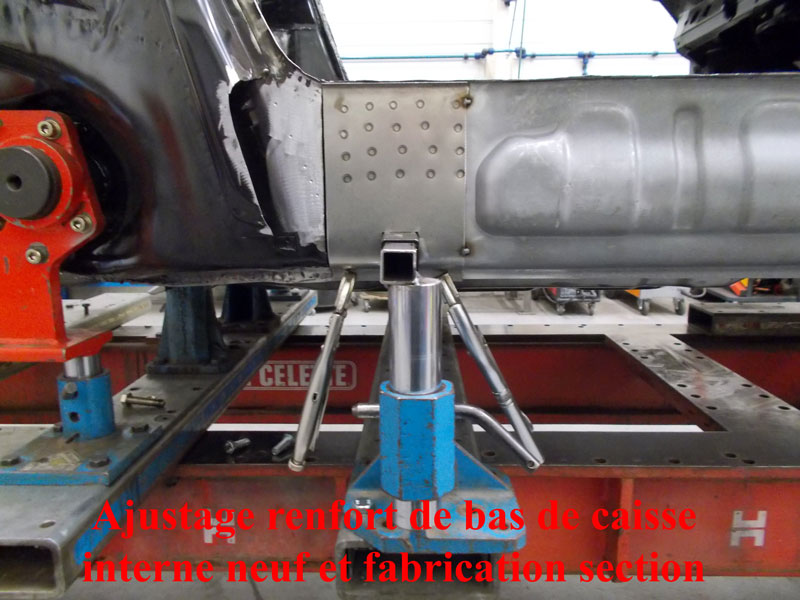

Repair of the lower body and the right jack support.

Adjustment and welding of the lower body reinforcement plate.

Adjustment and welding of the vertical reinforcement and the bottom of the door legs.

Fitting and welding of the inner Targa reinforcement.

Adjustment of the external hydraulic circuit.

The structure of the hull is finished, we move on to the repairs of the openings.

The undercarriages are dismantled and sandblasted.

Then they are chromated and a baked epoxy paint is applied.

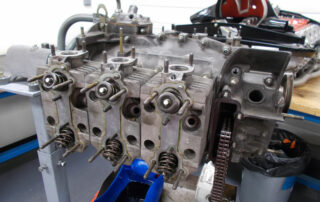

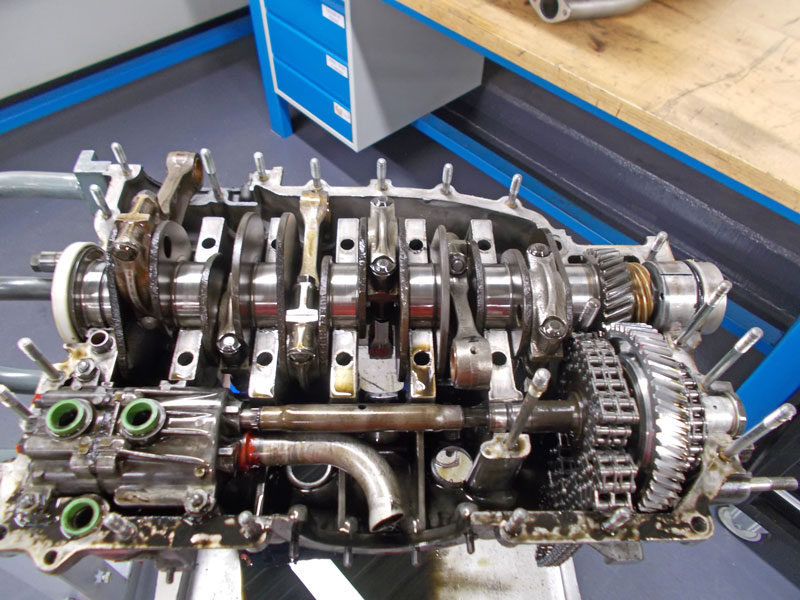

The restoration of the engine begins with its disassembly and metrology.

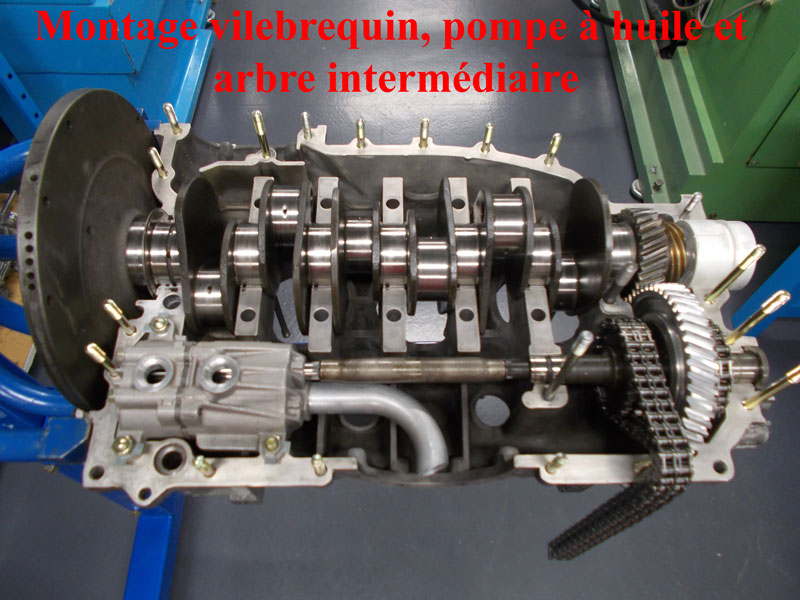

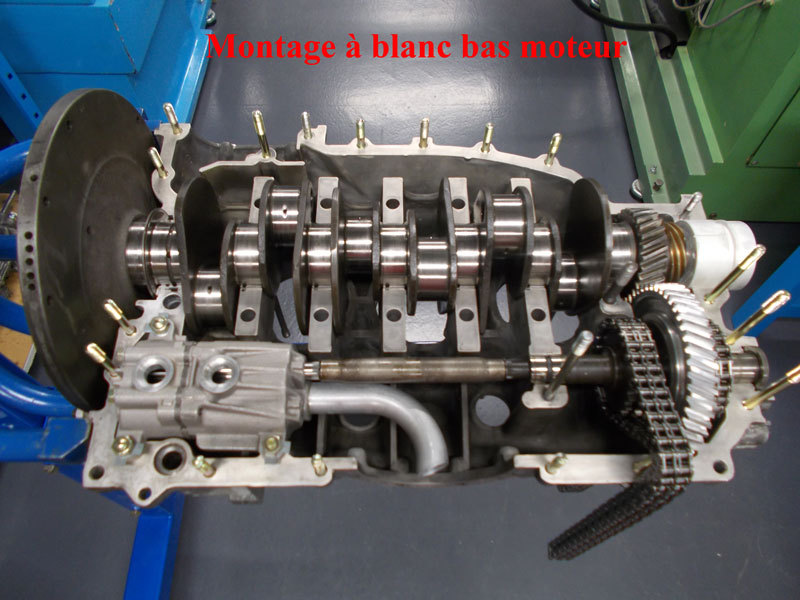

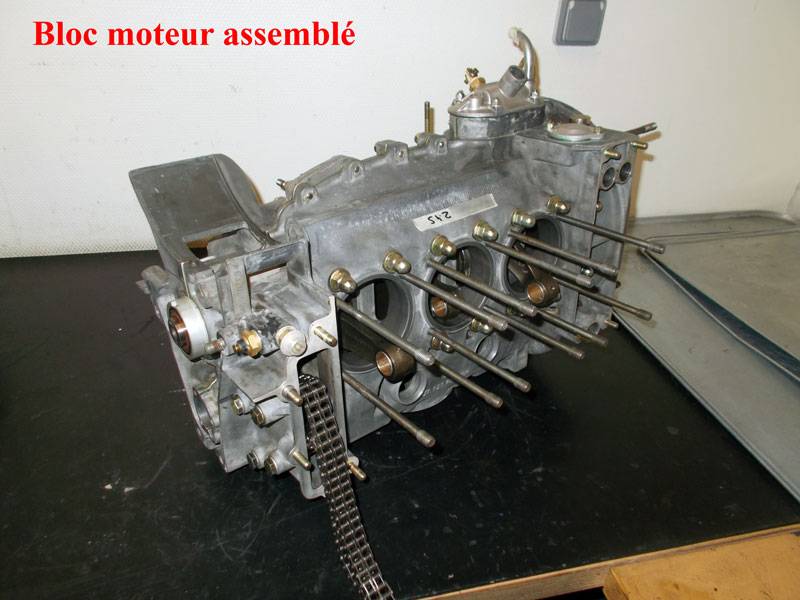

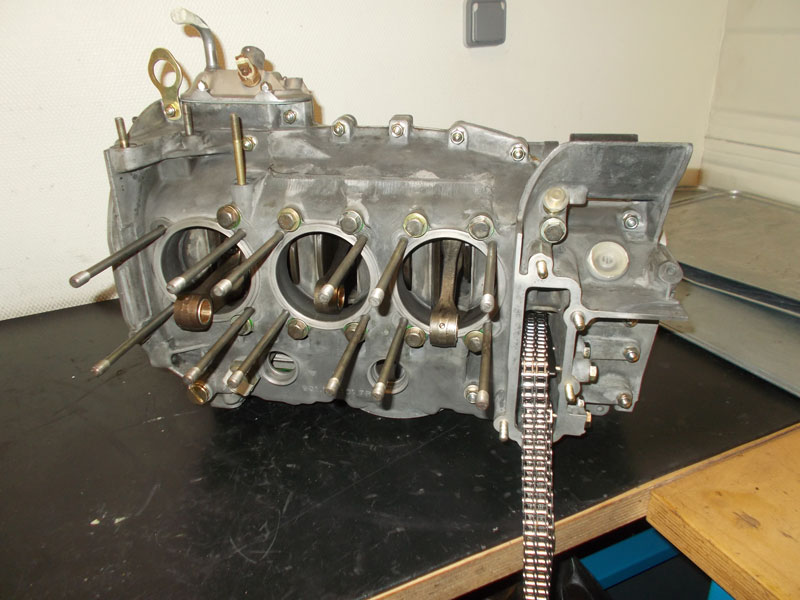

Crankshaft and engine block are still in original standard dimensions.

Many parts specific to the Model S have been replaced by Model E parts.

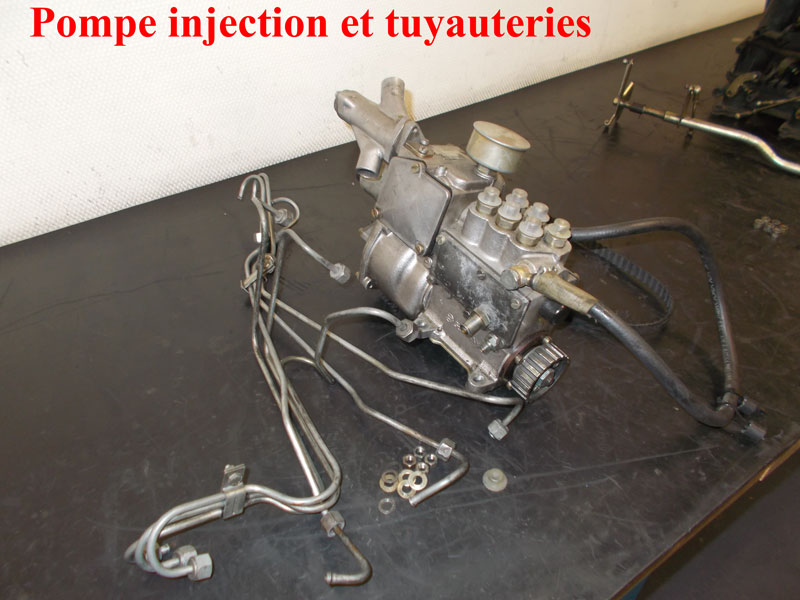

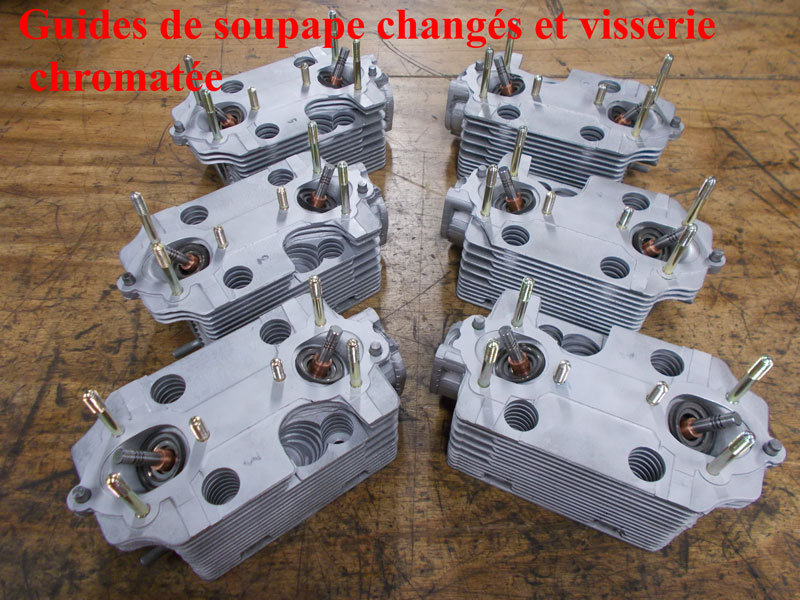

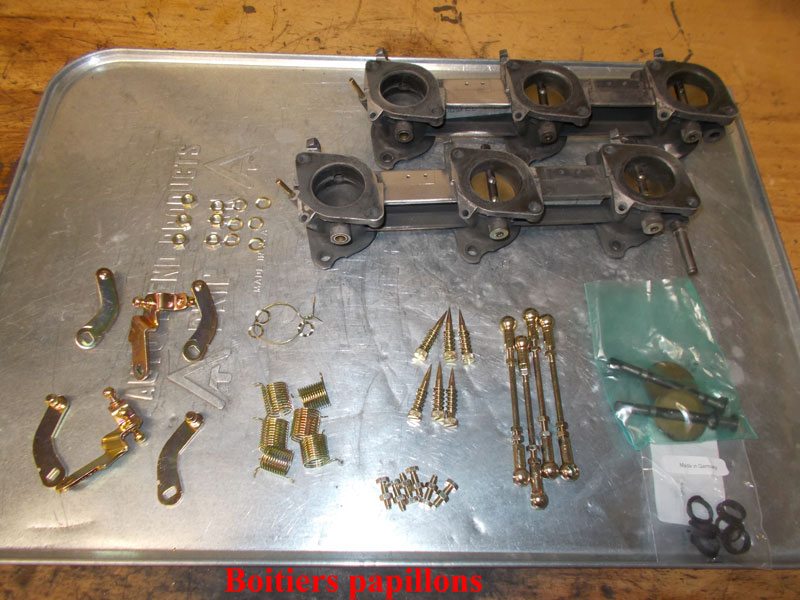

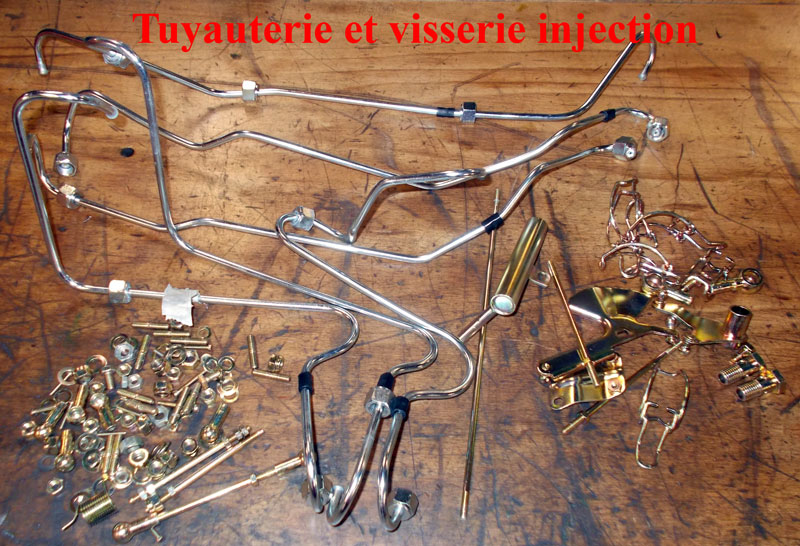

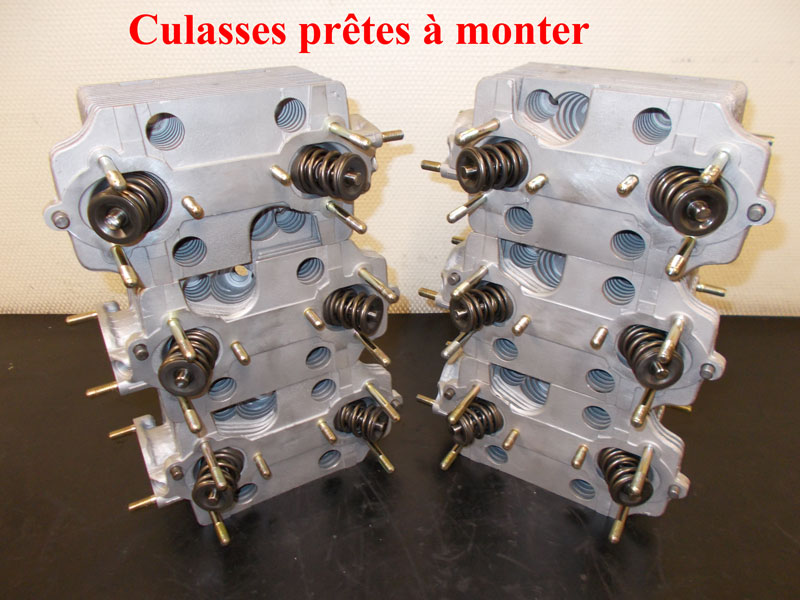

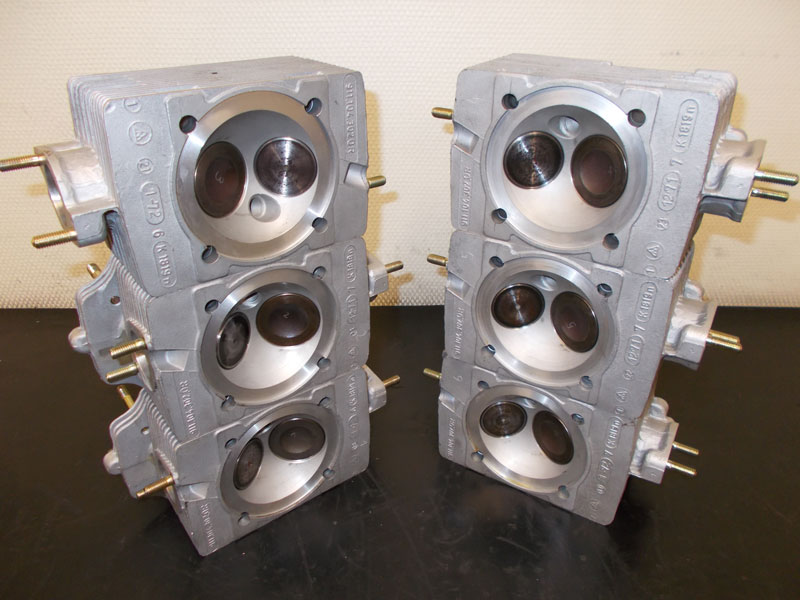

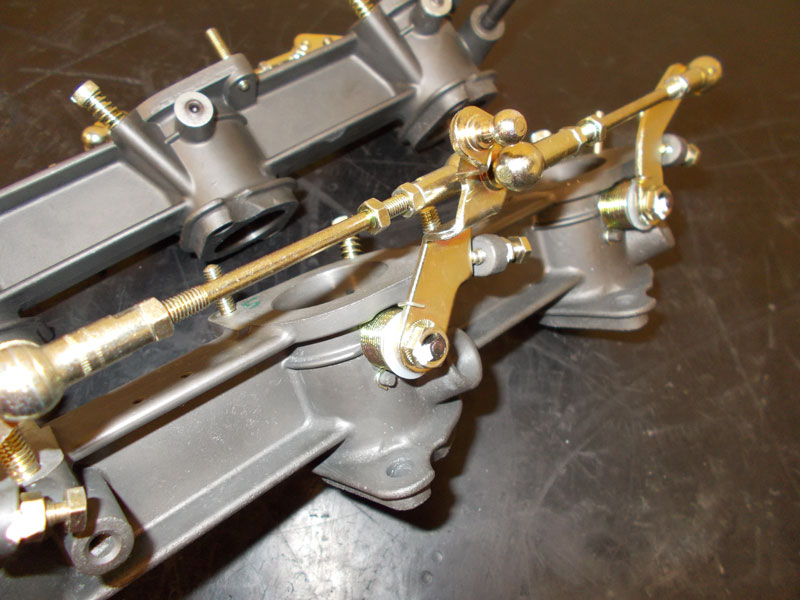

We need to find the S parts to put the engine back in its original configuration like pistons, cylinder heads, throttle bodies, intake pipes and injection pump.

The screws are chromated.

The original alternator is overhauled and tested.

The 2.4S injection pump is new.

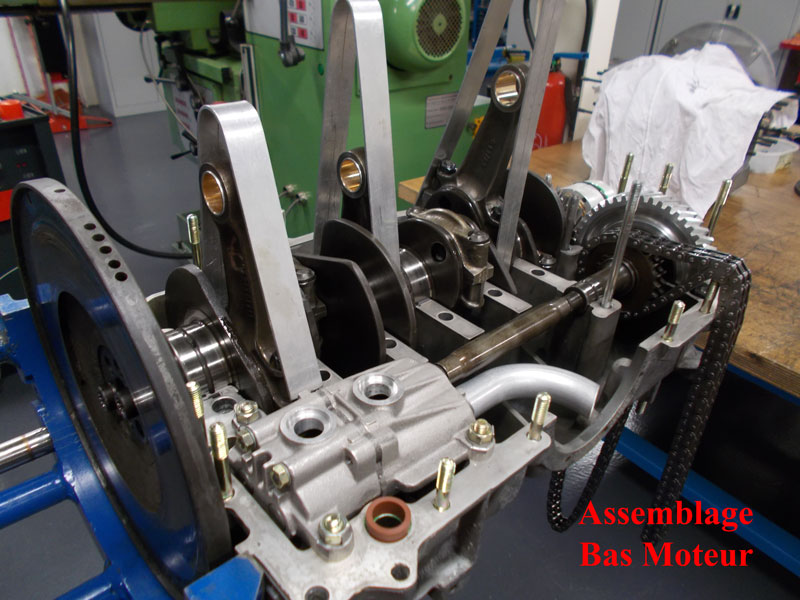

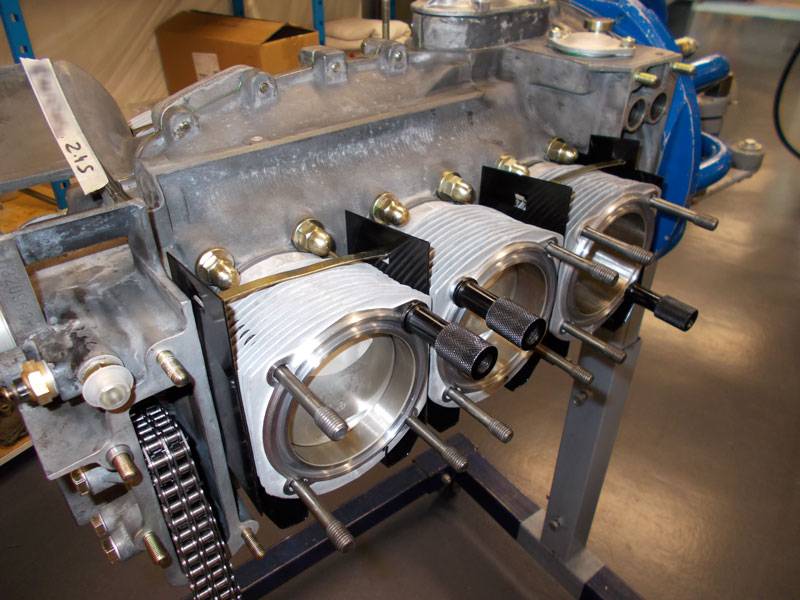

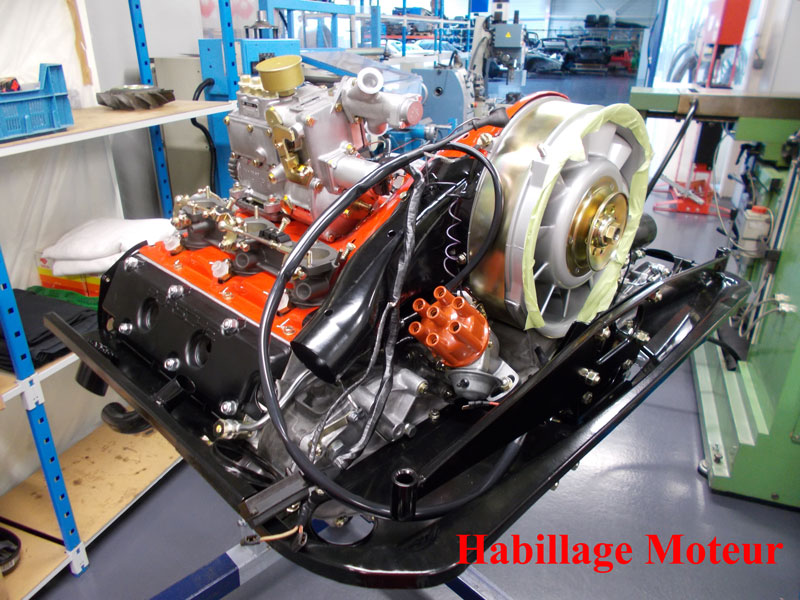

Assembly of the lower engine.

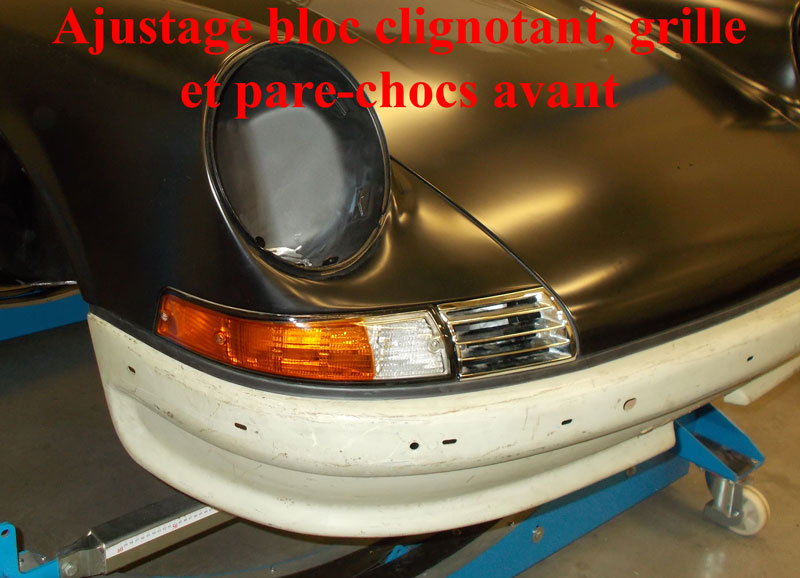

At the same time, the adjustment of the external bodywork continues.

All game settings are done with tin.

All the finishing details are treated with care.

When the hull comes out of the sheet metal shop, there is no more adjustment action needed, its protection can start.

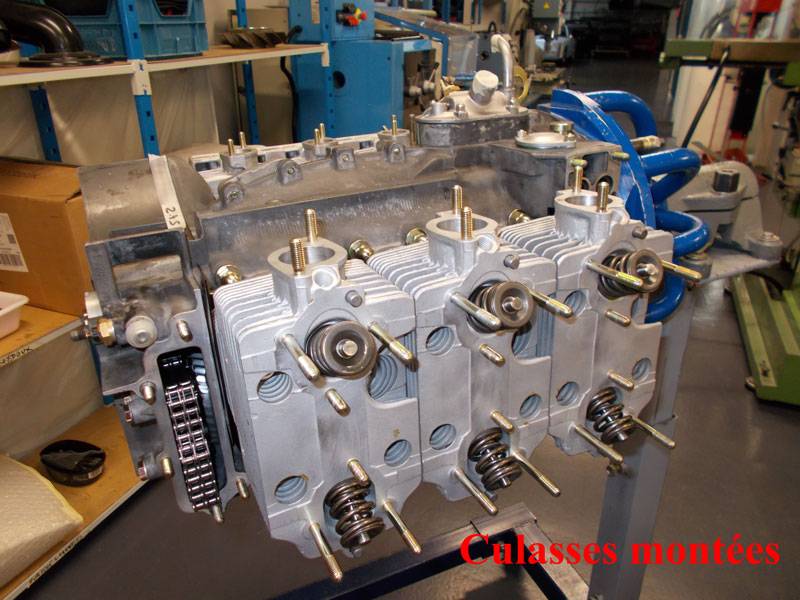

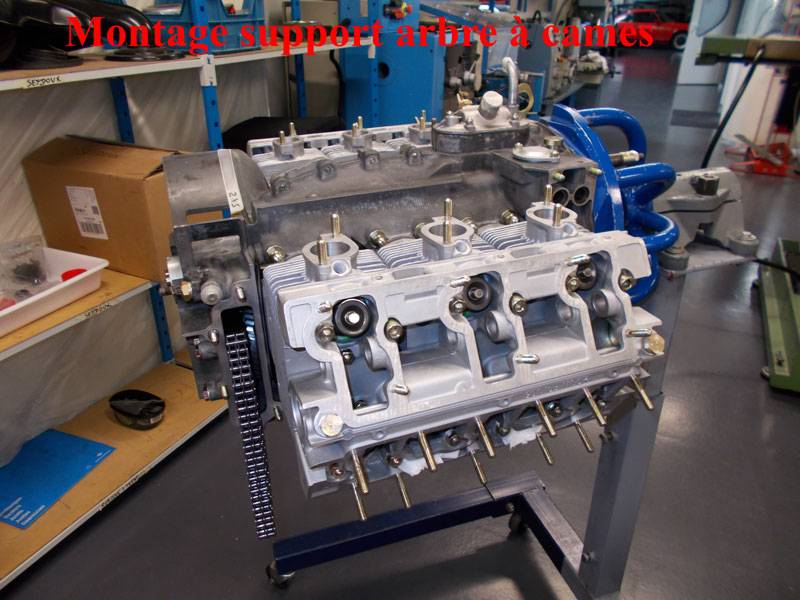

The assembly of the engine continues with the assembly of the cylinders, the cylinder heads and the camshaft supports.

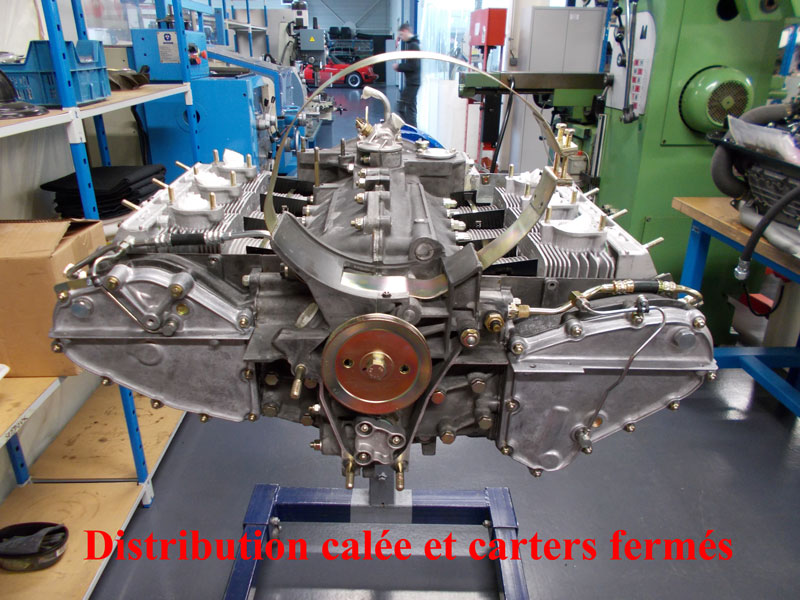

Assembly of the distribution.

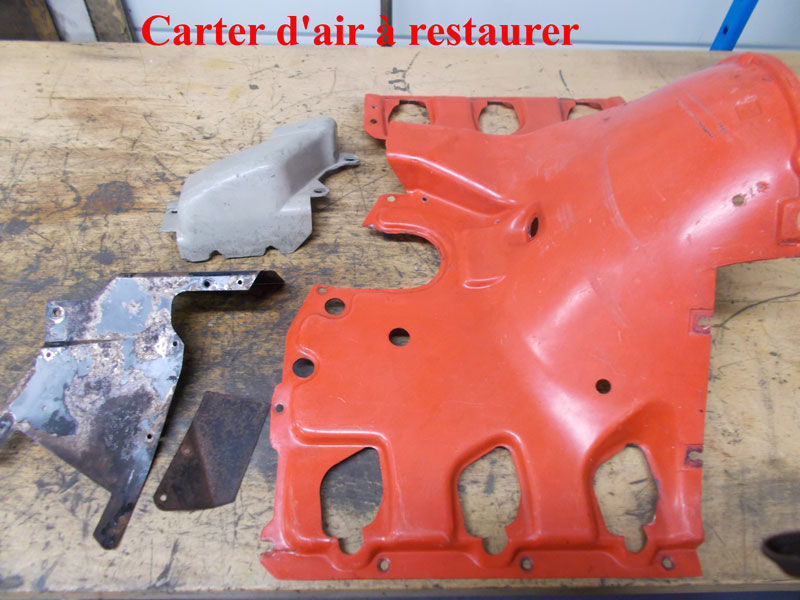

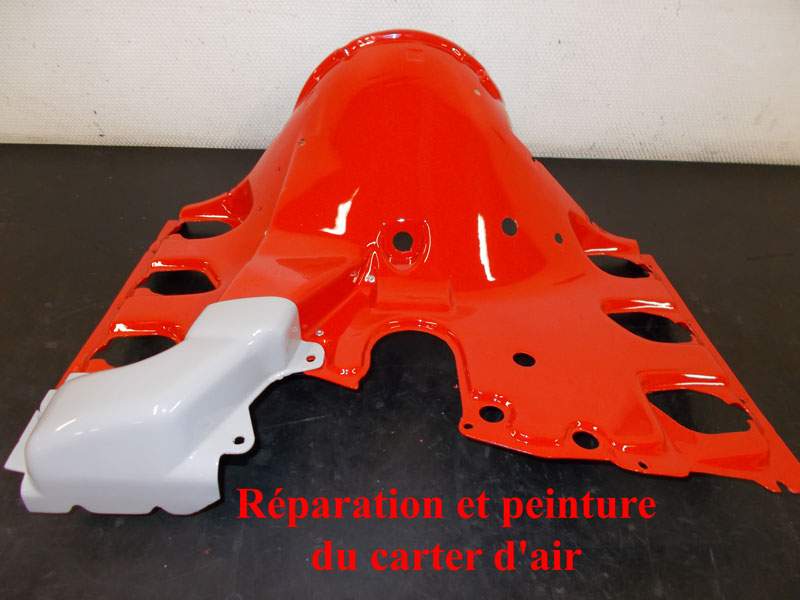

Engine cladding.

The hull and elements are sanded and then primed with epoxy.

The anti-gravels are applied and the interiors are painted.

The various primers are applied, sanded, and then the paint is applied.

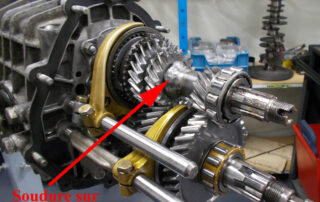

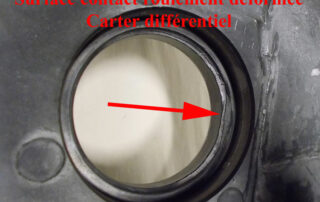

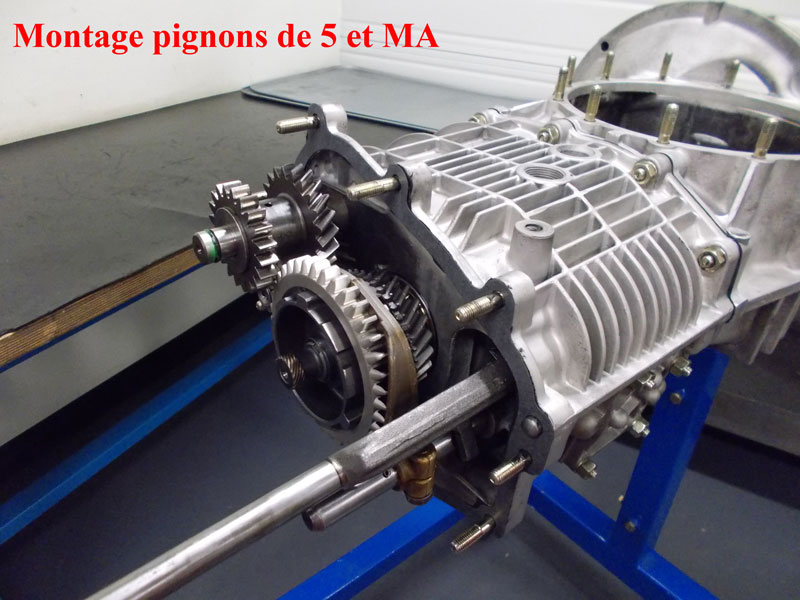

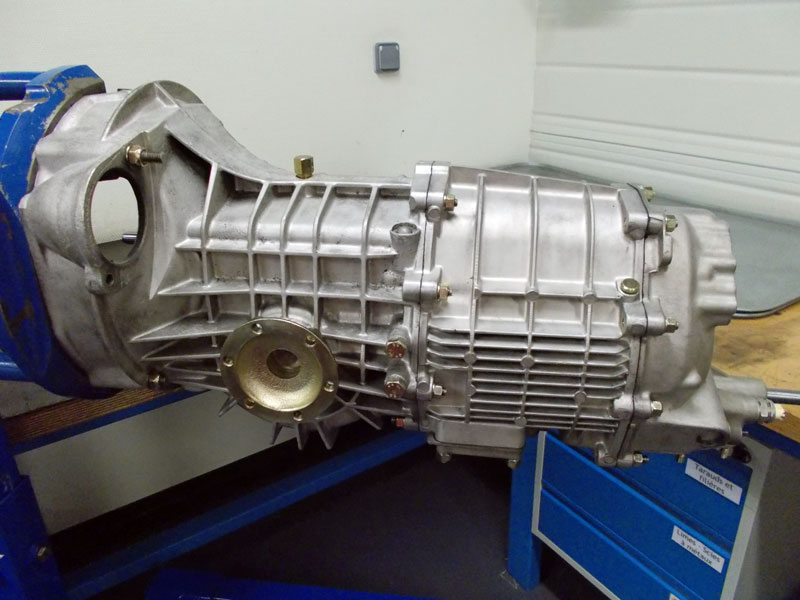

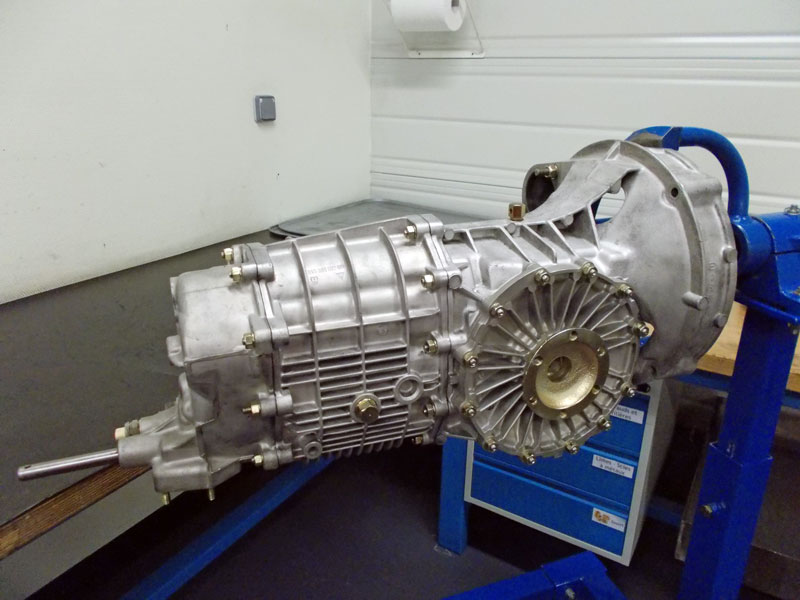

The gearbox is full of nasty surprises, as you can see on the pictures.

All bearings and seals shall be new.

New input shaft and bevel gear.

Assembly of the transmission.

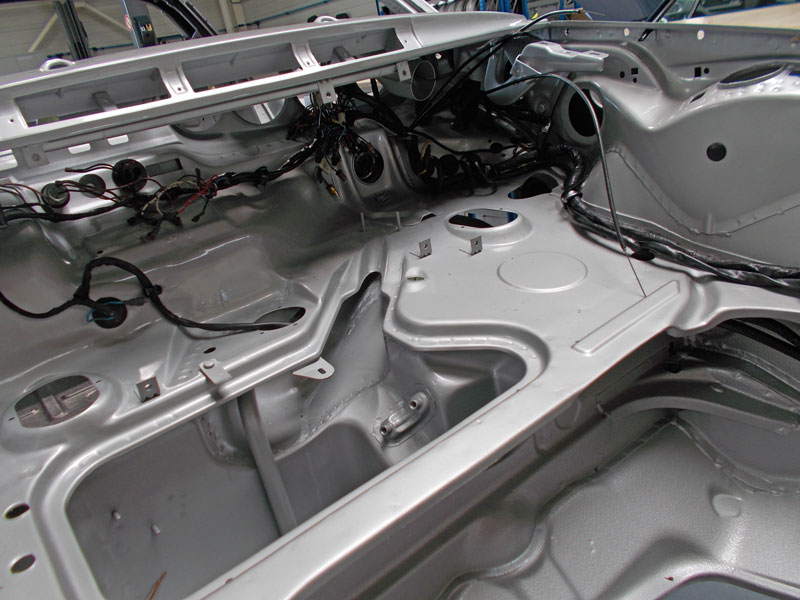

The reassembly of the car has begun.

Rehabilitation of the stainless steel arch.

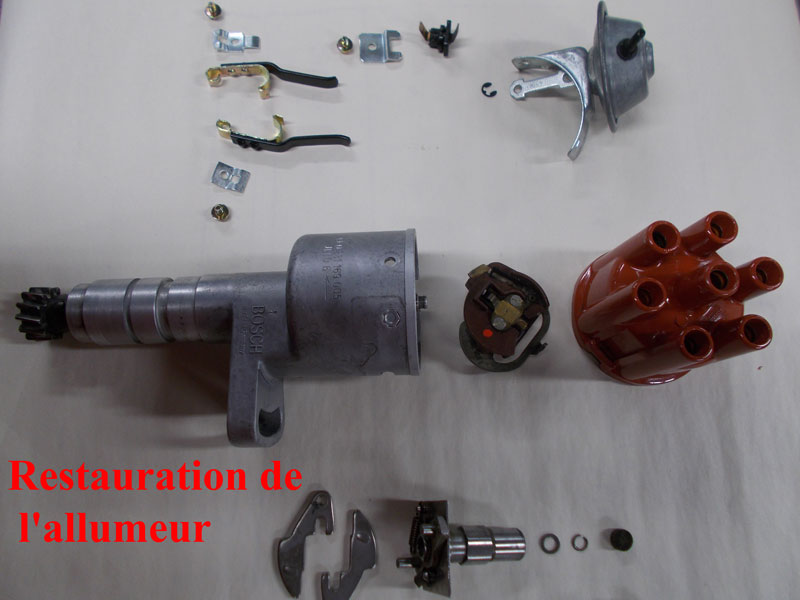

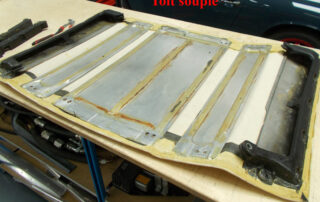

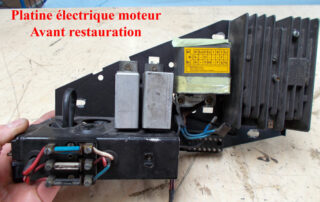

Repair of the flexible roof and the ignition plate.

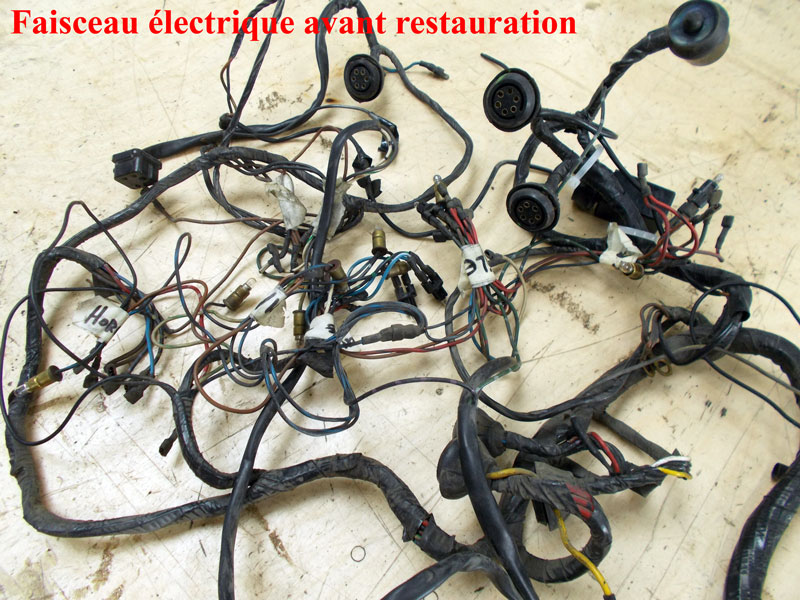

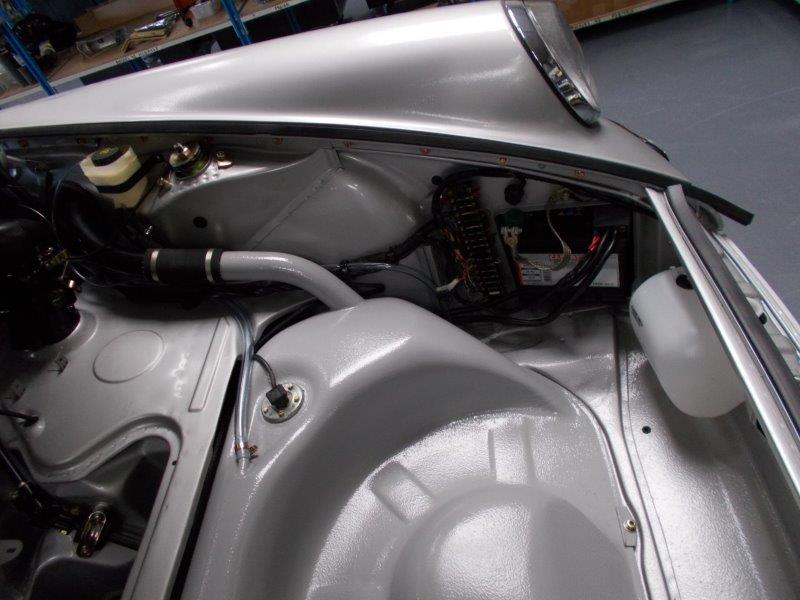

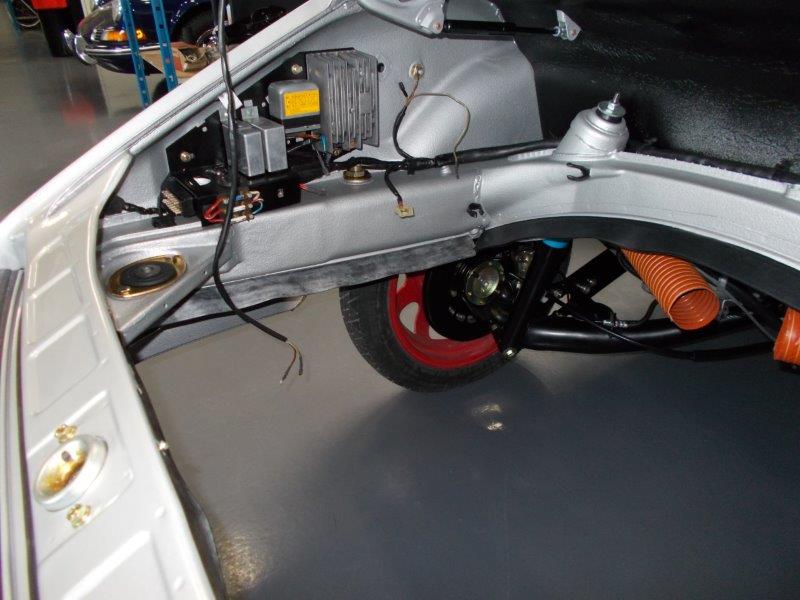

Rehabilitation of the electrical harness and assembly.

Installation of soundproofing. Reassembly of the fuel system.

Assembly of the running gear and the braking system.

Assembly of the hydraulic system and the front radiator.

Repair and assembly of the interior.

Realization of approximately 1,200 km to make all the necessary adjustments for a perfect operation.

Car ready for delivery…..

Mileage : km – Year : 1973 – Price :